Home

>

Products > Machining Center

> CNC Horizontal Machining Center

>

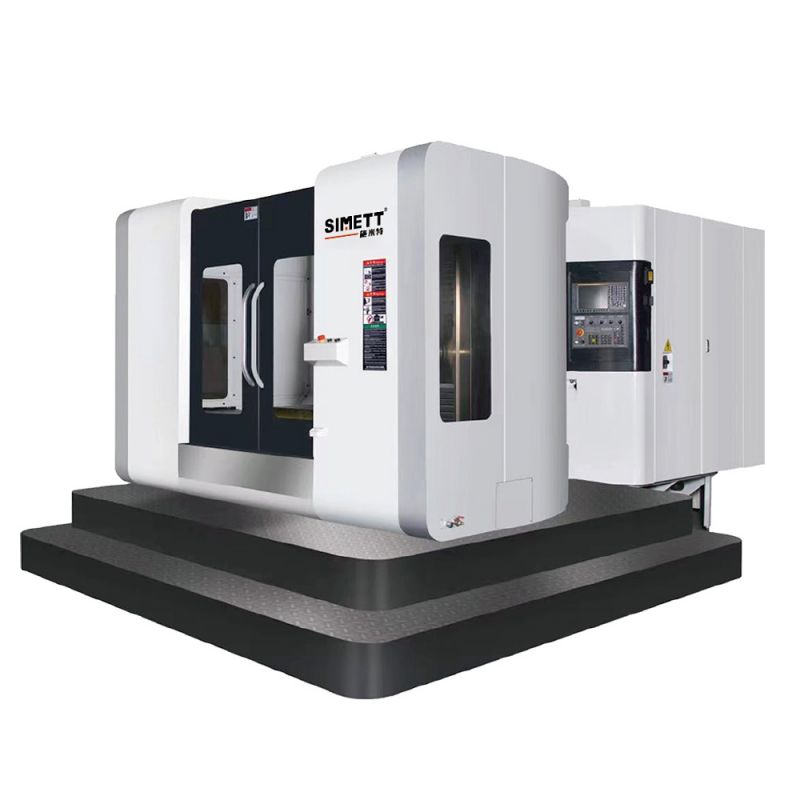

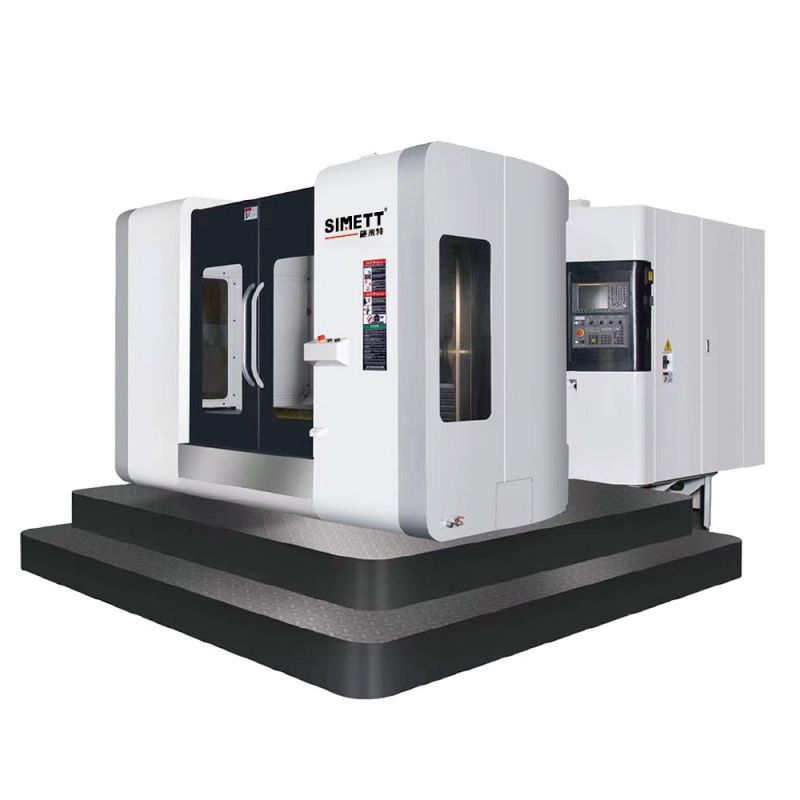

CNC Horizontal Machining Center 800

Products

CNC Horizontal Machining Center 800

SIMETT is a trailblazer in the industrial machinery sector, with a steadfast commitment to precision, innovation, and the development of advanced CNC solutions. As a prominent supplier of high-quality, durable, and technologically sophisticated CNC Horizontal Machining Center 800, SIMETT has set the standard for excellence in manufacturing.

Model:SMTHMC-800

Send Inquiry

Product Description

The company's customer-centric approach ensures that every product is designed to meet and exceed the evolving needs of the industry.The CNC Horizontal Machining Center 800 is a flagship model that embodies SIMETT's dedication to engineering excellence and technological advancement. This horizontal machining center is designed to provide professional manufacturers with a powerful, precise, and versatile tool capable of handling a wide array of tasks with ease.

Generous Travel Dimensions: With an X-axis travel of 1100mm, a Y-axis travel of 850mm, and a Z-axis travel of 900mm, the CNC Horizontal Machining Center 800 offers a substantial working envelope suitable for large and complex workpieces. Spindle Quill Diameter: The main spindle features a quill diameter of Φ190mm, accommodating a wide range of tooling options and ensuring compatibility with various machining operations.

Powerful Spindle Performance: Available in two high-power variants, 22KW or 26KW, the main spindle is designed to deliver robust performance for heavy-duty machining tasks.

Air Pressure Requirements: The CNC Horizontal Machining Center 800 operates efficiently with an air pressure source of 6~8bar, ensuring reliable functionality and ease of integration into various workshop environments.

Maximum Workpiece Swivel Diameter: The SMTHMC-800 is capable of handling workpieces with a maximum swivel diameter of φ1830mm, expanding the range of parts that can be machined efficiently.

The CNC Horizontal Machining Center 800 is a powerful, precise, and versatile machine that caters to the needs of professional operators who require a high level of control and precision in their machining processes.

Dynamic Response Capabilities: The system's dynamic response to operator commands ensures that the machine can keep up with the pace of modern, high-speed manufacturing processes.

Tool Management Precision: The CNC technology allows for precise tool management, with the ability to handle a wide range of tool sizes and types, thanks to the Φ190mm spindle quill diameter.

Customizable Control Software: The control software is highly customizable, allowing operators to tailor the CNC Horizontal Machining Center 800's performance to specific tasks and achieve optimal results.

Integrated Diagnostics: Advanced diagnostic features provide real-time monitoring and predictive maintenance capabilities, reducing downtime and increasing the machine's overall efficiency.

Network Connectivity: The CNC Horizontal Machining Center 800's CNC system is compatible with various network interfaces, facilitating integration into smart factory systems and enabling remote operation and monitoring.

Scalable Performance: The system's architecture allows for easy upgrades and expansions, ensuring that the CNC Horizontal Machining Center 800 can adapt to future technological advancements and remain at the forefront of machining

capabilities.

In summary, the CNC Horizontal Machining Center 800's advanced CNC technology positions it as a leader in modern machining, offering a blend of high-speed processing, dynamic response, and energy efficiency that is perfectly suited for the demands of contemporary manufacturing.

| Product Specifications |

|

| Machine Name: | CNC Horizontal Machining Center |

| Machine Model: | SMTHMC-800 |

| Travel: |

|

| X-Axis Travel (mm): | 1100 |

| Y-Axis Travel (mm): | 850 |

| Z-Axis Travel (mm): | 900 |

| The distance from the center of spindle to the table top (mm): | 0-850 |

| The distance from bottom of spindle to the center of table top (mm): | 180-1080 |

| Table Top: |

|

| The area of table top (mm): | 800*800 |

| The Max. Loading Weight (kgf): | 1500 |

| T-Shape Groove (WxNO.xP) (mm): | NO |

| Table Top Thread Hole: | 24-M16 |

| The Min. graduation of table top (°): | 1 |

| Spindle: |

|

| Spindle Taper: | BT50 |

| Spindle Speed (rpm): | 6000 |

| The diameter of spindle bush (mm): | Φ190 |

| The power of spindle (kW): | 22/26 |

| The driving type of spindle: | Belt-driven |

| The couterweight of Y-Axis: | Nitrogen Balancing Cylinder Block |

| Feed Speed: |

|

| The speed of X/Y/Z-Axis (m/min): | 24/24/24 |

| The speed of cutting feed (mm/min): | 1-6000 |

| Min. input unit (mm): | 0.001 |

| The power of servomotor of X/Y/Z-Axis (kW): | 3/3/3 |

| The width of X/Y/Z-Axis guideway (mm): | 55/55/55 |

| The type of X/Z-Axis guideway: | Roller Guideway |

| The type of Y-Axis guideway: | Roller Guideway |

| Automatic Blade Changing: |

|

| Cutting Tools Number (pcs): | 24 |

| Shank bolt: | P-50T(45°) |

| Max. cutting tool weight (kg): | 18 |

| Max. cutting tool length (mm): | 350 |

| Max. cutting tool diameter (mm): | Φ112 |

| Max. diameter between two cutting tools (mm): | Φ200 |

| The Time of tool changing (T to T) (sec): | 5 |

| The type of tool changing: | Twin Arm with Gripper |

| APC: |

|

| number of plate (pcs): | 2 |

| The type of exchanging: | rotation type |

| Max. revolving diameter of workpiece (mm): | φ1830 |

| Precision: |

|

| Positioning Precision (mm): | 0.015 |

| Repeat-Positioning Precision (mm): | 0.01 |

| Others: |

|

| Site Area (length*width) (mm): | 7700*4100 |

| Max. height of machine (mm): | 3950 |

| Machine weight (kg): | 12000 |

| Air Pressure (bar): | 6~8 |

| Electricity capacity (kVA): | 60 |

| CNC system: | FANUC-0iMF/MITSUBISHI-M80 |

| Accessories: √;X;O; "√" means the standard accessories; "X" means the NOT AVAILABLE accessories; "O" means the optional accessories | |

| Standard Accessories: | |

| The hear exchanger of electrical box | √ |

| Pre-pulled screw of Triple-axis | √ |

| Unclamping unit | √ |

| Automatic Feeding Lubricatinig Device | √ |

| All cover chip-free metal plate Cover | √ |

| Dust-free device of electrical box | √ |

| chip-free device with air curtain of the bottom of spindle | √ |

| Machine interior light | √ |

| Tricolor warning light | √ |

| rigidty tapping | √ |

| Foundation screw and block | √ |

| operating and maintenance manual | √ |

| Tool kit | √ |

| Types of spindle |

|

| belt-driven type 6000rpm | √ |

| belt-driven type 8000rpm | O |

| two-stage gear box 6000rpm | O |

| Oil cooler of spindle | √ |

| CTS system | O |

| Control System |

|

| FANUC-0iMF | √ |

| SIEMENS-828D | O |

| MITSUBISHI-M80 | O |

| KND | O |

| Cooling system |

|

| Cutting fluid cooling system | O |

| Spindle cooling ring | √ |

| workpiece blowing | √ |

| Chip conveying system |

|

| base chip-flushing function | √ |

| Top cover shower function | O |

| flushing water gun/ air gun | √ |

| chip conveying machine | O |

| Lubricating system |

|

| Automatic Oil Feeding Lubricatinig Device | √ |

| Automatic Grease Feeding Lubricatinig Device | O |

| ATC |

|

| BT50 Shank specification | √ |

| HSK Shank specification | O |

| 24T disc type tool magazine | √ |

| 30T disc type tool magazine | O |

| Error compensation system |

|

| X/Y-Axis grating ruler | O |

| X/Y/Z-Axis grating ruler | O |

| Electrical system accessories |

|

| Safety Door Security Device | O |

| Safety Door Security Device (CE) | O |

| Automatic contact breaking system | √ |

| The heat exchanger of electrical box | √ |

| The cooling air motor of electrical box | O |

| Cutting tool/ workpiece detective system |

|

| Automatic cutting tool length detector | O |

| Tool failure detector | O |

| Workpiece detector | O |

| Other Optional Accessories |

|

| The automatic door of apc side | O |

Generous Travel Dimensions: With an X-axis travel of 1100mm, a Y-axis travel of 850mm, and a Z-axis travel of 900mm, the CNC Horizontal Machining Center 800 offers a substantial working envelope suitable for large and complex workpieces. Spindle Quill Diameter: The main spindle features a quill diameter of Φ190mm, accommodating a wide range of tooling options and ensuring compatibility with various machining operations.

Powerful Spindle Performance: Available in two high-power variants, 22KW or 26KW, the main spindle is designed to deliver robust performance for heavy-duty machining tasks.

Air Pressure Requirements: The CNC Horizontal Machining Center 800 operates efficiently with an air pressure source of 6~8bar, ensuring reliable functionality and ease of integration into various workshop environments.

Maximum Workpiece Swivel Diameter: The SMTHMC-800 is capable of handling workpieces with a maximum swivel diameter of φ1830mm, expanding the range of parts that can be machined efficiently.

The CNC Horizontal Machining Center 800 is a powerful, precise, and versatile machine that caters to the needs of professional operators who require a high level of control and precision in their machining processes.

Dynamic Response Capabilities: The system's dynamic response to operator commands ensures that the machine can keep up with the pace of modern, high-speed manufacturing processes.

Tool Management Precision: The CNC technology allows for precise tool management, with the ability to handle a wide range of tool sizes and types, thanks to the Φ190mm spindle quill diameter.

Customizable Control Software: The control software is highly customizable, allowing operators to tailor the CNC Horizontal Machining Center 800's performance to specific tasks and achieve optimal results.

Integrated Diagnostics: Advanced diagnostic features provide real-time monitoring and predictive maintenance capabilities, reducing downtime and increasing the machine's overall efficiency.

Network Connectivity: The CNC Horizontal Machining Center 800's CNC system is compatible with various network interfaces, facilitating integration into smart factory systems and enabling remote operation and monitoring.

Scalable Performance: The system's architecture allows for easy upgrades and expansions, ensuring that the CNC Horizontal Machining Center 800 can adapt to future technological advancements and remain at the forefront of machining

capabilities.

In summary, the CNC Horizontal Machining Center 800's advanced CNC technology positions it as a leader in modern machining, offering a blend of high-speed processing, dynamic response, and energy efficiency that is perfectly suited for the demands of contemporary manufacturing.

Hot Tags: CNC Horizontal Machining Center 800, Manufacturer, Supplier, Factory, China, Wholesale, Buy, Customized, Made in China

Product Tag

Related Categories

Send Inquiry

Please feel free to fill your inquiry in the form below. We will reply you in 24 hours.

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy