Home

>

Products > Machining Center

> CNC Horizontal Machining Center

>

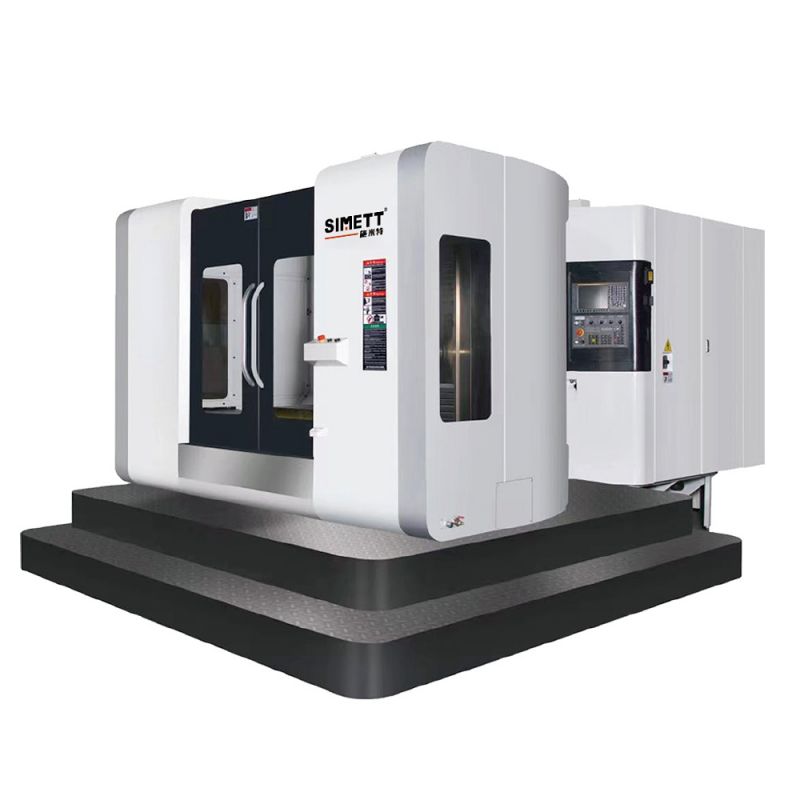

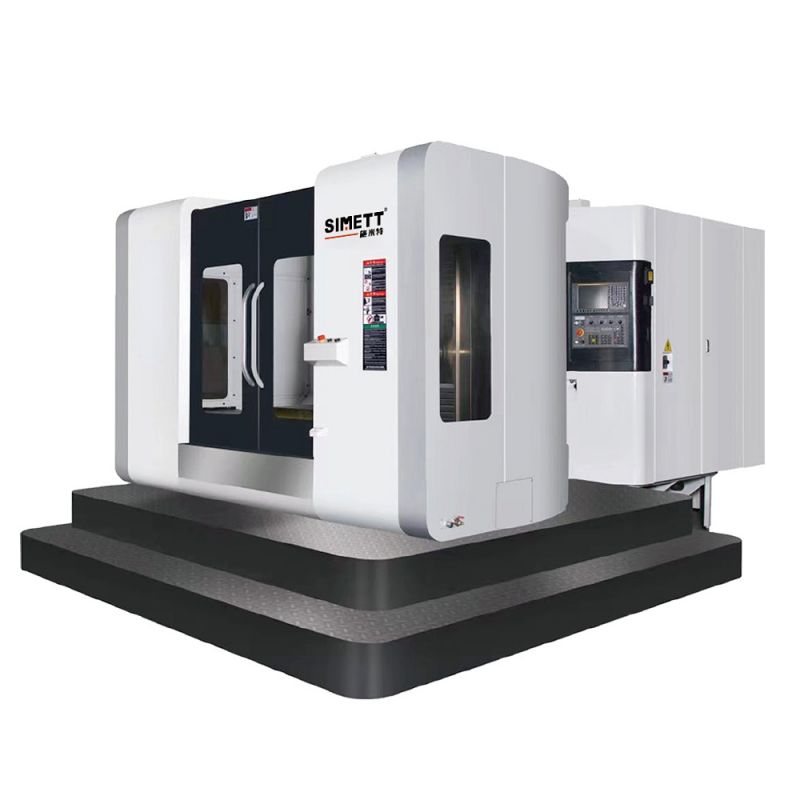

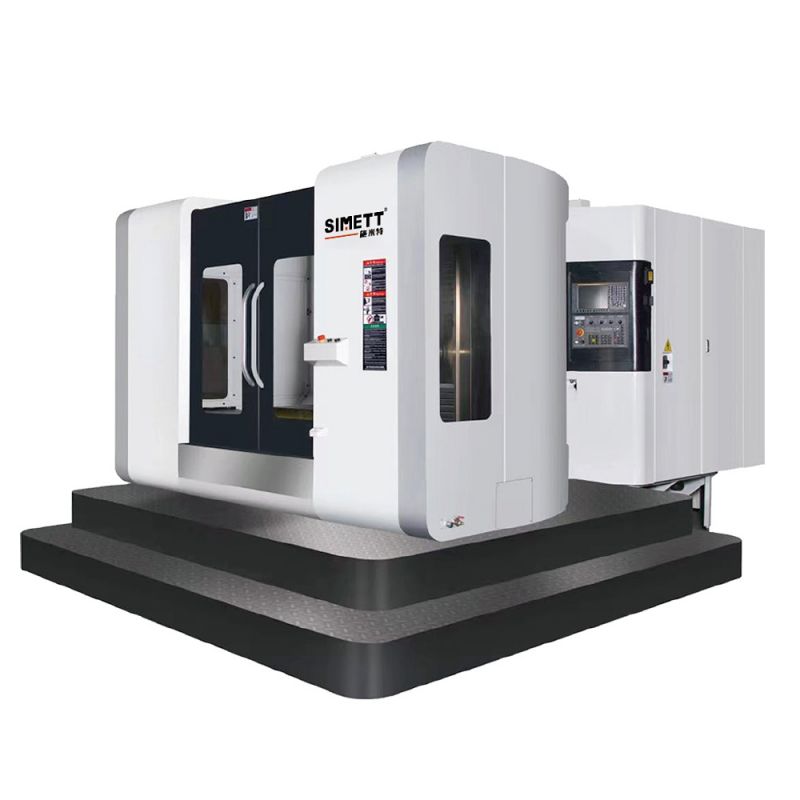

CNC Horizontal Machining Center 1075

Products

CNC Horizontal Machining Center 1075

SIMETT is a vanguard in the CNC Horizontal Machining Center 1075 manufacturing sector, distinguished by its steadfast commitment to precision engineering and a relentless pursuit of innovation. As a prominent supplier of advanced industrial machinery, SIMETT has earned a reputation for delivering durable, reliable, and technologically advanced CNC solutions.

Model:SMTHMC-1075

Send Inquiry

Product Description

With a customer-centric ethos at its core, SIMETT continues to redefine industry standards and set new benchmarks for excellence.The CNC Horizontal Machining Center 1075 is a pinnacle of SIMETT's expertise in high-performance CNC machinery. Engineered to excel in modern manufacturing demands, this horizontal machining center offers extensive travel capabilities and robust construction.

Travel Dimensions: With an X-axis travel of 1000mm, a Y-axis travel of 600mm, and a Z-axis travel of 750mm, the CNC Horizontal Machining Center 1075 is designed to manage a diverse array of workpieces and machining operations.

Spindle Taper: The BT50 spindle taper ensures compatibility with a wide range of tooling, providing secure and precise tool holding.

Spindle Speed: The CNC Horizontal Machining Center 1075's main spindle operates at speeds up to 6000 RPM, suitable for a variety of materials and part geometries, and adaptable for high-speed machining operations.

Spindle Power: Available in two robust power options, 7.5KW or 11KW, the main spindle is engineered for heavy-duty precision machining.

Y-Axis Counterweight System: The Nitrogen Balancing Cylinder Block on the Y-axis enhances stability and minimizes vibration for improved accuracy and surface finish.

Rapid Traverse Rates: The CNC Horizontal Machining Center 1075 offers rapid traverse rates of 24m/min for the X and Z axes, and 12m/min for the Y axis, optimizing productivity with swift repositioning.

Cutting Feed Rate: The cutting feed rate is adjustable from 1 to 6000mm/MIN, allowing for versatility in machining operations from roughing to finishing.

Advanced CNC Control: The latest CNC technology is integrated for automated and precise control over complex machining operations.

Durable Construction: The CNC Horizontal Machining Center 1075 is constructed with high-quality materials to ensure a long service life and consistent performance under demanding conditions.

Efficient Operation: The design focuses on operational efficiency, aiming to reduce energy consumption and maximize productivity.

The CNC Horizontal Machining Center 1075 is a testament to SIMETT's dedication to empowering manufacturers with machines that offer exceptional precision, control, and adaptability in their machining processes. SIMETT aims to deepen its relationships with customers, becoming a trusted advisor and partner in their journey towards operational excellence. The company is dedicated to designing machinery that is not only efficient but also environmentally conscious, contributing to a sustainable future for the manufacturing industry. Through these strategic plans, SIMETT is poised to not only maintain its reputation for excellence but also to shape the future of manufacturing with a commitment to innovation, customer success, and global growth.

Travel Dimensions: With an X-axis travel of 1000mm, a Y-axis travel of 600mm, and a Z-axis travel of 750mm, the CNC Horizontal Machining Center 1075 is designed to manage a diverse array of workpieces and machining operations.

| Product Specifications |

|

| Machine Name: | CNC Horizontal Machining Center |

| Machine Model: | SMTHMC-1075 |

| Travel: |

|

| X-Axis Travel (mm): | 1000 |

| Y-Axis Travel (mm): | 600 |

| Z-Axis Travel (mm): | 750 |

| The distance from the center of spindle to the table top (mm): | 65~665 |

| The distance from bottom of spindle to the center of table top (mm): | 80~830 |

| Table Top: |

|

| The area of table top (mm): | 1300*600 |

| The Max. Loading Weight (kgf): | 800 |

| T-Shape Groove (WxNO.xP) (mm): | 18*5*100 |

| Table Top Thread Hole: | NO |

| The Min. graduation of table top (°): | 1 |

| Spindle: |

|

| Spindle Taper: | BT50 |

| Spindle Speed (rpm): | 6000 |

| The diameter of spindle bush (mm): | Φ190 |

| The power of spindle (kW): | 7.5/11 |

| The driving type of spindle: | Belt-driven |

| The couterweight of Y-Axis: | Nitrogen Balancing Cylinder Block |

| Feed Speed: |

|

| The speed of X/Y/Z-Axis (m/min): | 24/12/24 |

| The speed of cutting feed (mm/min): | 1~6000 |

| Min. input unit (mm): | 0.001 |

| The power of servomotor of X/Y/Z-Axis (kW): | 3/3/3 |

| The width of X/Y/Z-Axis guideway (mm): | 45/55 |

| The type of X/Z-Axis guideway: | Roller Guideway |

| The type of Y-Axis guideway: | Hard guideway |

| Automatic Blade Changing: |

|

| Cutting Tools Number (pcs): | 24 |

| Shank bolt: | P-50T(45°) |

| Max. cutting tool weight (kg): | 18 |

| Max. cutting tool length (mm): | 350 |

| Max. cutting tool diameter (mm): | Φ112 |

| Max. diameter between two cutting tools (mm): | Φ200 |

| The Time of tool changing (T to T) (sec): | 5 |

| The type of tool changing: | Twin Arm with Gripper |

| APC: |

|

| number of plate (pcs): | 1 |

| The type of exchanging: | NO |

| Max. revolving diameter of workpiece (mm): | NO |

| Precision: |

|

| Positioning Precision (mm): | 0.015 |

| Repeat-Positioning Precision (mm): | 0.01 |

| Others: |

|

| Site Area (length*width) (mm): | 3500*3000 |

| Max. height of machine (mm): | 2800 |

| Machine weight (kg): | 6500 |

| Air Pressure (bar): | 6~8 |

| Electricity capacity (kVA): | 40 |

| CNC system: | FANUC-0iMF/MITSUBISHI-M80 |

| Accessories: √;X;O; "√" means the standard accessories; "X" means the NOT AVAILABLE accessories; "O" means the optional accessories | |

| Standard Accessories: | |

| The hear exchanger of electrical box | √ |

| Pre-pulled screw of Triple-axis | √ |

| Unclamping unit | √ |

| Automatic Feeding Lubricatinig Device | √ |

| All cover chip-free metal plate Cover | √ |

| Dust-free device of electrical box | √ |

| chip-free device with air curtain of the bottom of spindle | √ |

| Machine interior light | √ |

| Tricolor warning light | √ |

| rigidty tapping | √ |

| Foundation screw and block | √ |

| operating and maintenance manual | √ |

| Tool kit | √ |

| Types of spindle |

|

| belt-driven type 6000rpm | O |

| belt-driven type 8000rpm | √ |

| two-stage gear box 6000rpm | O |

| Oil cooler of spindle | √ |

| CTS system | O |

| Control System |

|

| FANUC-0iMF | √ |

| SIEMENS-828D | O |

| MITSUBISHI-M80 | O |

| KND | O |

| Cooling system |

|

| Cutting fluid cooling system | O |

| Spindle cooling ring | √ |

| workpiece blowing | √ |

| Chip conveying system |

|

| base chip-flushing function | √ |

| Top cover shower function | O |

| flushing water gun/ air gun | √ |

| chip conveying machine | O |

| Lubricating system |

|

| Automatic Oil Feeding Lubricatinig Device | √ |

| Automatic Grease Feeding Lubricatinig Device | O |

| ATC |

|

| BT50 Shank specification | √ |

| HSK Shank specification | O |

| 24T disc type tool magazine | √ |

| 30T disc type tool magazine | O |

| Error compensation system |

|

| X/Y-Axis grating ruler | O |

| X/Y/Z-Axis grating ruler | O |

| Electrical system accessories |

|

| Safety Door Security Device | O |

| Safety Door Security Device (CE) | O |

| Automatic contact breaking system | √ |

| The heat exchanger of electrical box | √ |

| The cooling air motor of electrical box | O |

| Cutting tool/ workpiece detective system |

|

| Automatic cutting tool length detector | O |

| Tool failure detector | O |

| Workpiece detector | O |

| Other Optional Accessories |

|

| The automatic door of apc side | O |

Spindle Taper: The BT50 spindle taper ensures compatibility with a wide range of tooling, providing secure and precise tool holding.

Spindle Speed: The CNC Horizontal Machining Center 1075's main spindle operates at speeds up to 6000 RPM, suitable for a variety of materials and part geometries, and adaptable for high-speed machining operations.

Spindle Power: Available in two robust power options, 7.5KW or 11KW, the main spindle is engineered for heavy-duty precision machining.

Y-Axis Counterweight System: The Nitrogen Balancing Cylinder Block on the Y-axis enhances stability and minimizes vibration for improved accuracy and surface finish.

Rapid Traverse Rates: The CNC Horizontal Machining Center 1075 offers rapid traverse rates of 24m/min for the X and Z axes, and 12m/min for the Y axis, optimizing productivity with swift repositioning.

Cutting Feed Rate: The cutting feed rate is adjustable from 1 to 6000mm/MIN, allowing for versatility in machining operations from roughing to finishing.

Advanced CNC Control: The latest CNC technology is integrated for automated and precise control over complex machining operations.

Durable Construction: The CNC Horizontal Machining Center 1075 is constructed with high-quality materials to ensure a long service life and consistent performance under demanding conditions.

Efficient Operation: The design focuses on operational efficiency, aiming to reduce energy consumption and maximize productivity.

The CNC Horizontal Machining Center 1075 is a testament to SIMETT's dedication to empowering manufacturers with machines that offer exceptional precision, control, and adaptability in their machining processes. SIMETT aims to deepen its relationships with customers, becoming a trusted advisor and partner in their journey towards operational excellence. The company is dedicated to designing machinery that is not only efficient but also environmentally conscious, contributing to a sustainable future for the manufacturing industry. Through these strategic plans, SIMETT is poised to not only maintain its reputation for excellence but also to shape the future of manufacturing with a commitment to innovation, customer success, and global growth.

Hot Tags: CNC Horizontal Machining Center 1075, Manufacturer, Supplier, Factory, China, Wholesale, Buy, Customized, Made in China

Product Tag

Related Categories

Send Inquiry

Please feel free to fill your inquiry in the form below. We will reply you in 24 hours.

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy